2024 Calendar:

August 27 – 28, Phoenix, AZ

Click here for registration form

For immediate assistance or to schedule this course for your group, please contact:

Sharon Montana-Beard

Toll Free, 1-888-837-9959 X208

Email: [email protected]

August 27 – 28, Phoenix, AZ

Click here for registration form

For immediate assistance or to schedule this course for your group, please contact:

Sharon Montana-Beard

Toll Free, 1-888-837-9959 X208

Email: [email protected]

Documented by the Department of Commerce, Counterfeit Electronic components have now infiltrated 40% of the US Pentagon’s supply chain. No longer can we turn a deaf ear or look the other way. The subject is nothing to be ashamed of or embarrassed about if counterfeit material invades your immediate supply chain. It has reached an epidemic level worldwide. The effects are astonishing: in our research, 98% of the organizations ProSkill CTG has worked with in one form or another have been affected by counterfeit electronic components.

It is no speculation to state that every large and small contract manufacturer in the world has had their own run-in with suspect counterfeit electronic components. The problem has escalated over the past few years, making product sales from counterfeiting astronomical. It is estimated that over 600 Billion dollars a year is made worldwide from the sale of counterfeited products and knockoffs.

The new US counterfeit component law HR1540 Section 818 was signed into effect on December 31, 2011 by the President of the United States. Training courses like what ProSkill CTG offers explains this law in detail and what it actually means to your company.

Are you being defrauded by counterfeiters selling counterfeited material with the possibly of it ending up in your customers product? Quality contract manufacturers who include a robust counterfeit parts protection program is important. The more information presented, the more you will know about counterfeit components and risk mitigation.

The greatest concern globally is a national or international security breach or loss of life as counterfeit electronic components continue to saturate supply chains around the world.

Electronic Manufacturing companies need to work together and commit to mitigating the risk of counterfeit components. Open conversation between customers, and component suppliers is absolutely critical for the identification and management of risks

associated with counterfeit components.

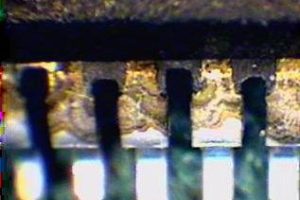

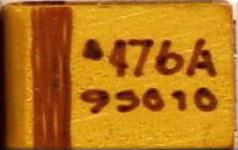

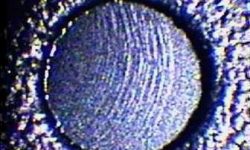

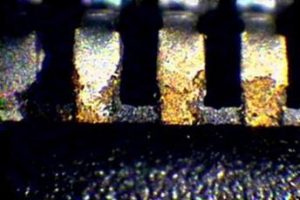

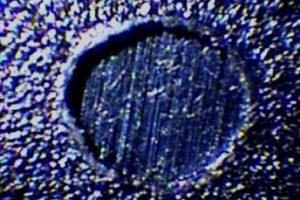

Improved incoming inspection is crucial and must be in-place for counterfeit component detection. Internal component lot traceability systems should be used to track components through the manufacturing process.

The chance for infiltration of counterfeit components into the supply chain increases every step away from the OCM, (Original Component Manufacturer). Original Equipment Manufacturers using EMS counterfeit prevention is a daunting chore. The OEM’s exposure to the risks is directly tied to their Electronic Component Supplier. A commitment preventing counterfeit components from entering their supply chain is essential. Selecting a well-informed and subject-educated EMS (Electronic Manufacturing Service) provider is critical in the prevention of counterfeit electronic components ending up in military, medical, or commercial equipment.

In closing, due diligence is the most important part of a strong defense against counterfeit material. Never leave anything to chance; maintaining your guard is the strategy necessary for mitigating risk. Preventing a counterfeit component invasion into your supply chain is very possible, providing there is in place a systematic reduction of exposure to the risk.

Adhering to the points mentioned above will certainly help your company in the prevention of Counterfeit Components from entering your supply chain.