IPC Certification and the Professional Development of Your Employees

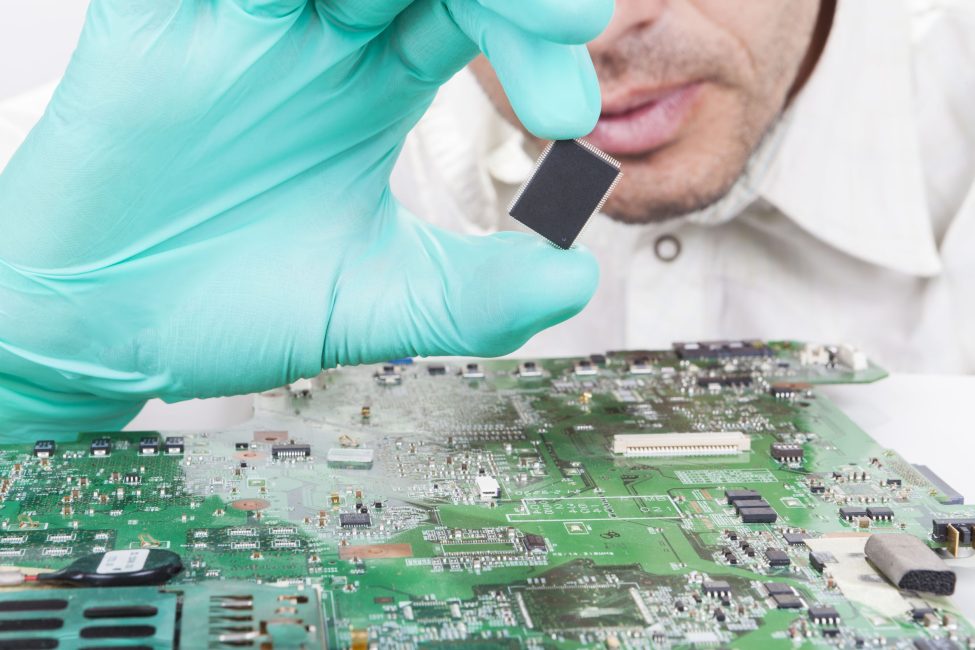

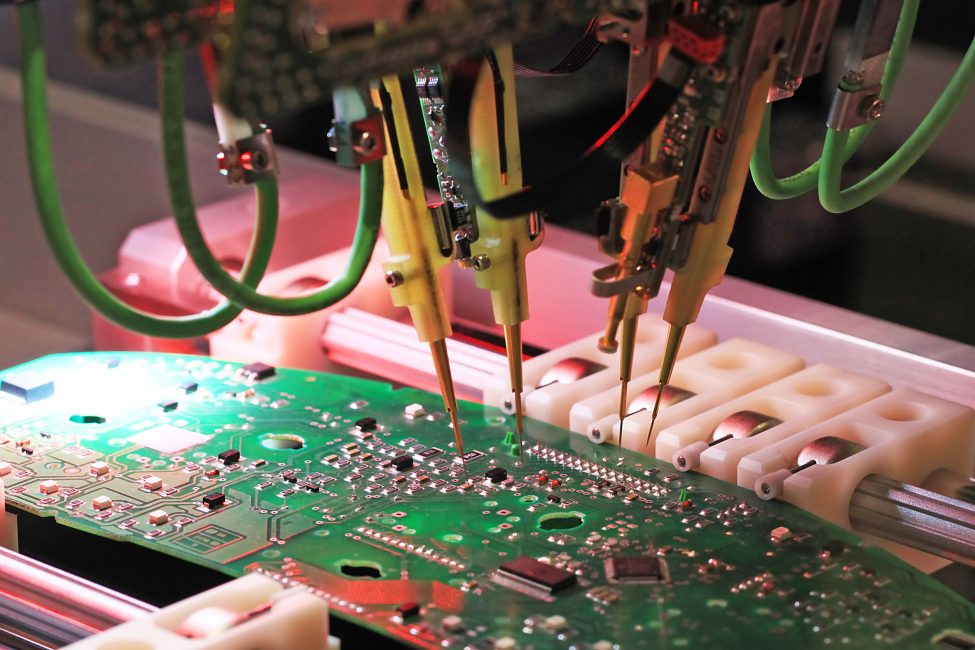

Designed to interconnect all segments of the electronics manufacturing sector, training and courses built around IPC standards bring positive value to the electronics industry. IPC courses and training are delivered by certified trainers through educational classes, training workshops, technical conferences, and webcasts…

Details